A closer look at our comprehensive solid-state characterisation and optimisation services:

Our capabilities support every stage of development – from early pre-formulation to commercialisation and lifecycle management. These include:

- Advanced solid-state characterisation

- Polymorph screening and tendency studies

- Salt selection and optimisation studies

- Co-crystallisation and form setting crystallisation development

- Impurity control crystallisation

- Kinetic and thermodynamic solubility assessments and modelling

- Pre-formulation and non-clinical formulation development

- Physical form definition and progression

Advanced techniques that enable rapid, high-quality analysis and decision-making:

Built for flexibility, precision, and scale-up - leveraging techniques including:

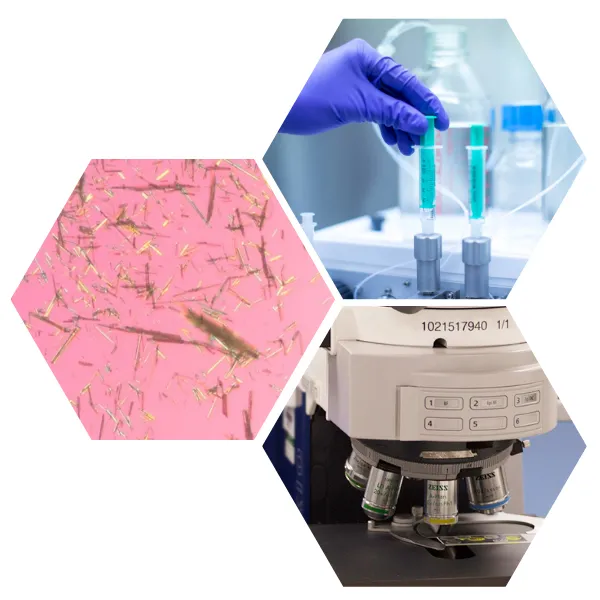

- X-Ray Powder Diffraction (XRPD)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Solid-State NMR spectroscopy

- Dynamic Vapour Sorption (DVS)

- FTIR spectroscopy

- Optical microscopy

- Surface area analysis

Arcinova: Your partner in solid-state science

Strengthen your formulation with smart salt selection

Polymorph screening that ensures full physical characterisation and reduces manufacturing risk

Detailed evaluation of a drug substance’s physicochemical properties is critical to enable robust manufacturing, fulfil regulatory requirements, and ensure consistent product performance. Fully characterising the selected physical form and evaluating its stability is critical for regulatory success, IP protection, and risk reduction in drug development and manufacturing.

Accelerate API isolation and purification through integrated solid-state support

Choosing the right salt or polymorphic form early helps improve yield, purity and process efficiency. Our solid-state team works hand-in-hand with Process Research & Development to rapidly determine salt forms and map polymorphic landscapes to integrate crystallisation development with process optimisation – ensuring the selected form enhances yield, solubility, stability and chemical purity.

Bring your candidate to clinic faster with pre-formulation screening support

Our experienced material scientists support early pre-formulation screening to identify the most suitable form of your drug substance – with the right physicochemical properties to progress into preclinical and early clinical development. Our integrated approach streamlines decision-making, supports better candidate selection, and lays the foundation for a successful drug product.

Our end-to-end drug substance development capabilities bring together process research, analytical science, solid-state expertise and GMP manufacture – all from our state-of-the-art facility in Alnwick, UK. Working in close collaboration, we deliver tailored solutions for even the most complex development programs – from route selection and process optimisation to CPP definition, DoE, and impurity control.

With integrated solid-form screening and selection, we ensure the most suitable form is identified ahead of manufacture, supporting faster, smoother progression to IND/IMPD and beyond.